- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

PT1000 vs PT100 1/30B level sensors: How to choose industrial temperature measurement? This article explains it thoroughly! How to translate

PT1000 vs PT100 1/30B level sensors: How to choose industrial temperature measurement? This article explains it thoroughly!

How to translate

How many precision anxieties have you experienced in industrial temperature measurement?

In semiconductor manufacturing workshops, temperature fluctuations of ± 0.5 ° C can lead to a 5% decrease in wafer yield; In chemical reaction vessels, overheating by 1 ° C may trigger a chain reaction - the "accuracy tolerance" of industrial temperature measurement is always zero. But when faced with two types of high-precision sensors on the market, PT100 1/30B and PT1000 1/30B, many engineers will ask:

Why is the price difference of 20% when both are labeled as' 1/30B level '? Which one should I choose? ”

This article combines the IEC 60751 standard and 10+industry customer test data to help you thoroughly solve the selection problem from three dimensions: "technical differences → scenario adaptation → cost considerations".

1、 The core pain point of industrial temperature measurement: balancing accuracy and cost

1.1 Temperature accuracy requirements for industrial scenarios

Temperature measurement in the industrial field has never been "just about the same":

Semiconductor: The curing temperature of photoresist should be controlled within ± 0.3 ° C;

Chemical industry: Temperature fluctuations in catalytic reactions exceeding ± 0.5 ° C can lead to a 10% decrease in product purity;

Food processing: The temperature deviation for pasteurization is ± 1 ° C, which may cause food safety issues.

The common requirement for these scenarios is to have both high precision and stable reliability - which is the core value of 1/40B level sensors.

1.2 1/30B level: Not all "B-levels" are the same

According to the IEC 60751 standard, the accuracy levels of platinum resistors are divided into A, B, 1/3B, 1/10B, 1/30B, etc. among which

Ordinary B-level: 0 ° C~100 ° C error ± 0.3 ° C, full range error ± 0.6 ° C;

1/40B level: 0 ° C~100 ° C error ≤± (0.3+0.005 × | T |) ° C (T is the temperature value), full range error is only ± 0.5 ° C - accuracy improvement of 20%, more suitable for wide temperature range scenarios.

Simply put, 1/40B level is the "top student in B-level", suitable for industrial scenarios with higher precision requirements.

2、 What are the essential differences between PT1000 and PT100 1/30B levels?

2.1 Resistance Base: The Key to Determining Signal Stability

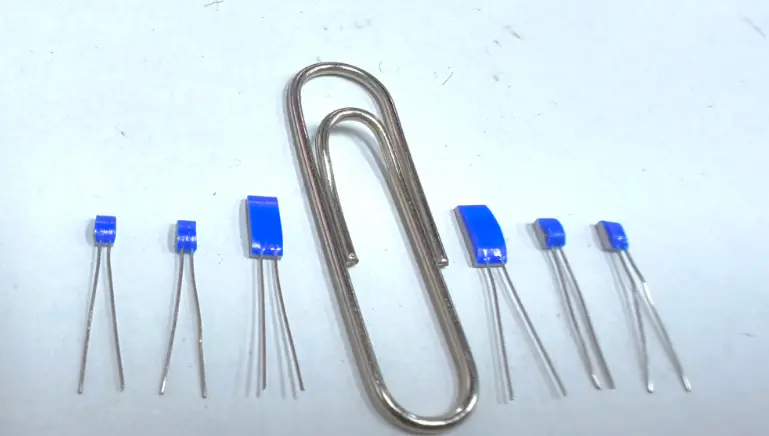

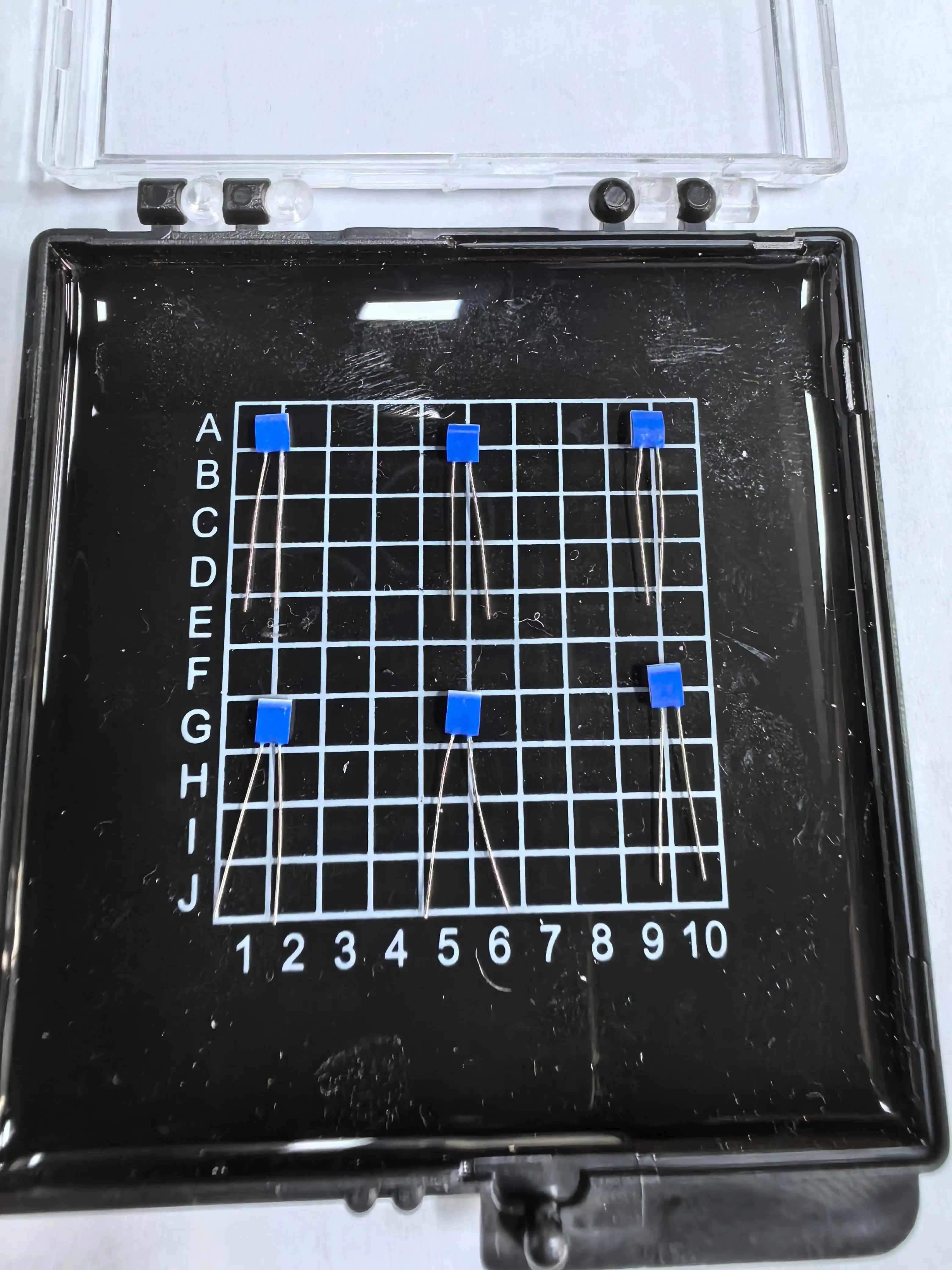

The core difference between PT100 (100 Ω) and PT1000 (1000 Ω) lies in the resistance base of the platinum resistor:

PT1000: High resistance value means "less interference from wire resistance" - for example, a 100m long copper wire with a resistance of about 0.1 Ω contributes 0.1% to the measurement error of PT100 and only 0.01% to PT1000;

PT100: Low resistance is more suitable for "short distance, low-cost" scenarios, such as temperature monitoring of small devices.

2.2 Application scenarios: Long distance vs compact space

Scenario recommendation model reason: Long distance pipeline temperature measurement PT1000 reduces wire resistance error and ensures accurate end data. Small equipment temperature monitoring PT100 has a small volume and a 15%~20% lower cost of supporting circuits. High temperature furnaces (>200 ° C) PT1000 have better resistance stability at high temperatures, with a drift rate lower than PT100. Third, measured data: Why is PT1000 more suitable for industrial scenarios?

We conducted comparative tests at a certain automotive parts factory:

Environment: Workshop temperature of 25 ° C, wire length of 150m;

• Result:

PT100: Measurement error ± 0.4 ° C (wire resistance contribution of 0.1 ° C, sensor drift of 0.3 ° C);

PT1000: Measurement error ± 0.1 ° C (wire resistance contribution 0.01 ° C, sensor drift 0.09 ° C).

Factory engineer feedback: "After switching to PT1000, the qualified rate of heat treatment temperature for engine cylinder blocks has increased from 92% to 98%, reducing waste losses by 80000 yuan per month. ”

Conclusion: Choosing the right sensor makes industrial temperature measurement more worry free

Choose PT1000 1/30B level: If your scene is "long-distance, high interference, high temperature";

Choose PT100 1/30B level: If your requirements are "low cost, compact space, short distance".

No matter which one is chosen, a precision of 1/30B is the "safety line" for industrial temperature measurement - after all, temperature error is never a "small matter".

FAQ: The 5 Most Concerned Questions for Engineers

1. How much is PT1000 more expensive than PT100?

A: The unit price is 10% to 15% higher, but in the long run, the reduced waste losses far exceed the cost difference.

2. Q: Does 1/30B level require additional calibration?

A: No need - our products have undergone three-point calibration from -50 ° C to 350 ° C before leaving the factory, in compliance with ISO 17025 standard.

3. Q: Can PT1000 be used in an environment of -70 ° C?

A: Sure - our PT1000 1/30B class operates within a temperature range of -70 ° C to+350 ° C.

CTA: Get customized solutions immediately

Xi'an Tongzida Technology Co., Ltd. is a leading manufacturer and supplier of advanced thermistor technology, dedicated to providing high-performance temperature sensors for demanding industrial applications. We have comprehensive expertise in microsensor manufacturing technology, special packaging technology, and multi-sensor integration methods to ensure excellent performance and reliability of thermistors. As a trusted supplier of precision temperature measurement solutions, we offer a complete thermistor system, including core sensitive chips, testing systems, and analysis software. Please contact our technical experts sales11@xatzd.com Discuss your specific thermistor requirements and learn how our advanced resistor temperature optimization and manufacturing capabilities can improve the performance and reliability of your temperature measurement system

References

1. IEC 60751:2008 standard for industrial platinum resistance thermometers;

2. Optimization Report on Heat Treatment Temperature Control of a certain automotive parts factory;

3. Siemens' "Industrial Temperature Sensor Selection Guide".

Learn about our latest products and discounts through SMS or email