- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What to Look for in a Platinum Resistance Thermistor Supplier for Industrial Automation?

What to Look for in a Platinum Resistance Thermistor Supplier for Industrial Automation?

Choosing the right supplier for platinum resistance thermistors is just as critical as selecting the sensor itself. For industrial automation, a reliable supplier ensures consistent quality, on-time delivery, and technical support—factors that directly impact your operational efficiency. This article outlines the key criteria to evaluate when sourcing platinum resistance thermistors for automation.

Quality Assurance and Compliance

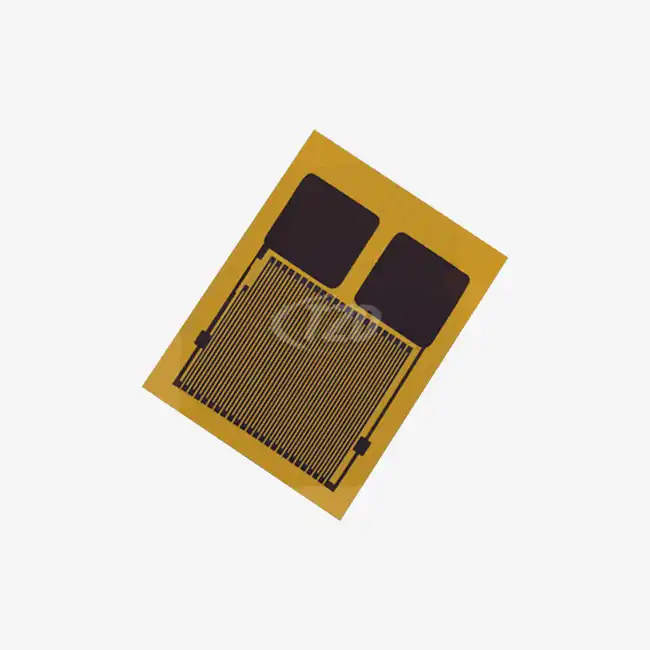

Industrial automation demands sensors that meet strict quality and safety standards, so prioritize suppliers with robust quality assurance (QA) processes. Look for suppliers certified to ISO 9001 and IATF 16949 (for automotive automation). Ensure their platinum resistance thermistors comply with IEC 60751:2022, the global standard for industrial platinum RTDs.

Reputable suppliers provide traceability documentation, including material certificates (for high-purity platinum) and calibration reports. This ensures your platinum resistance thermistors meet specifications (3850 ppm/°C TCR, ≤±0.04% drift) and supports compliance with industry regulations (GMP, FDA, AEC-Q200 for automotive).

Customization Capabilities for Automation Needs

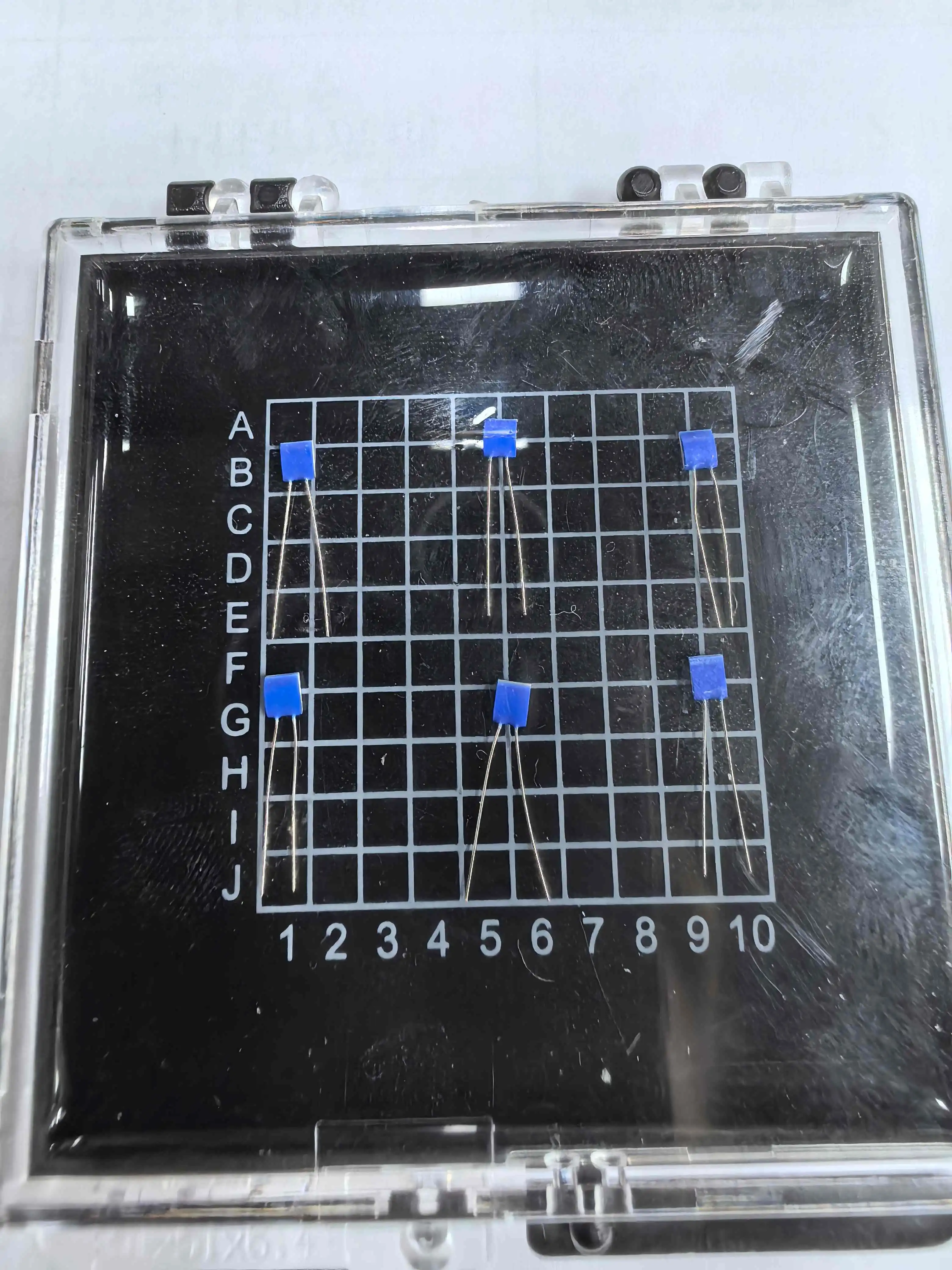

Every automation system has unique requirements, so avoid suppliers with limited product ranges. The best suppliers offer customization options tailored to industrial automation, including:

Lead materials (platinum-nickel, silver-palladium, pure platinum/pure silver) for corrosive or high-precision applications.

Packaging (vacuum plastic, waterproof, cleanroom-grade) to fit harsh or controlled environments.

Lead specifications (length, diameter) and sensor dimensions (2.0mm×2.3mm×1.0mm, 2.0mm×4.0mm×1.0mm) for tight spaces.

Suppliers with in-house engineering teams can also develop custom solutions for unique automation challenges, such as high-vibration or extreme-temperature processes.

Supply Chain Stability and Delivery Reliability

Industrial automation lines can’t afford delays, so supplier delivery reliability is non-negotiable. Look for suppliers with a proven track record of on-time delivery (≥95% on-time rate) and flexible lead times (standard 4-week lead times, expedited options for urgent orders). Ask about their inventory management—suppliers with local warehouses (for欧美 markets) can reduce shipping time and costs.

Evaluate their supply chain resilience. The best suppliers source raw materials from multiple vendors and have contingency plans for disruptions (e.g., geopolitical issues, logistics delays). This ensures consistent availability of platinum resistance thermistors, even during market fluctuations.

Technical Support and Post-Sale Service

Industrial automation sensors often require technical expertise during integration and maintenance, so prioritize suppliers with responsive support teams. Look for 24/7 technical support (for global automation facilities) and access to engineers who understand your application (e.g., automotive heat treatment, robotics).

Post-sale service is also critical. Reputable suppliers offer warranty coverage (minimum 1-year warranty), calibration services, and replacement parts. They should also provide resources like wiring guides, installation manuals, and application case studies to help you get the most out of your platinum resistance thermistors.

FAQ: Choosing a Platinum Resistance Thermistor Supplier

Q: For global automation operations, should I choose a local or international supplier? A: Opt for an international supplier with local support (warehouses, technical teams) in your target markets. This balances cost-effectiveness with fast delivery and on-site support.

Q: How can I verify a supplier’s quality claims? A: Request sample sensors for testing, review customer testimonials (from automation industries), and ask for third-party certification reports (IEC 60751, ISO).

Q: What’s more important—price or quality when choosing a supplier? A: Quality and reliability take priority. Cheap suppliers may cut corners on materials (low-purity platinum) or QA, leading to sensor failures and costly downtime.

Conclusion & CTA

When sourcing platinum resistance thermistors for industrial automation, prioritize suppliers that offer quality assurance, customization, supply chain stability, and technical support. These factors ensure your sensors integrate seamlessly, perform reliably, and support long-term automation efficiency.

Looking for a trusted platinum resistance thermistor supplier for your automation needs? Our team meets all the criteria above—ISO-certified quality, flexible customization, global delivery, and 24/7 technical support. Contact us today to discuss your requirements and request a free sample or quote.

Author Information:

[Li Yi] is a procurement specialist for industrial automation, with expertise in sensor sourcing and supplier management. He helps manufacturers build resilient supply chains for critical components.

References:

1. “Supplier Evaluation Criteria for Industrial Sensors” – Industrial Automation Magazine, 2024.

2. IEC 60751:2022. Industrial platinum resistance thermometers and platinum temperature sensors.

Industrial automation experts consistently recommend platinum resistance thermistors for temperature monitoring. But what makes these sensors the top choice? This article shares insights from industry professionals, highlighting the key benefits that set platinum RTDs apart.

Xi'an Tongzida Technology Co., Ltd. is a leading manufacturer and supplier of advanced thermistor technology, focusing on providing high-performance temperature sensors for demanding industrial applications. We have profound expertise in microsensor manufacturing, specific packaging technologies, and multi-sensor integration methods, which ensures the excellent performance and reliability of our thermistors. As a trusted supplier of precision temperature measurement solutions, we offer a complete thermistor system, including sensor chips, testing systems, and analysis software. Please feel free to contact our technical experts at any time. ventes11@xatzd.com Discuss your specific requirements for thermistors and learn how our advanced thermal resistor optimization and manufacturing capabilities can enhance the performance and reliability of your temperature measurement system.

Learn about our latest products and discounts through SMS or email